Centres of Excellence, which bring scientists together from different fields – such as material science, electronics, chemical engineering and theoretical physics – with common purpose, inevitably spark discoveries that weren’t even considered at the outset.

As a consequence of ongoing collaborations within FLEET, researchers made a series of liquid-metal discoveries opening pathways towards sustainable science.

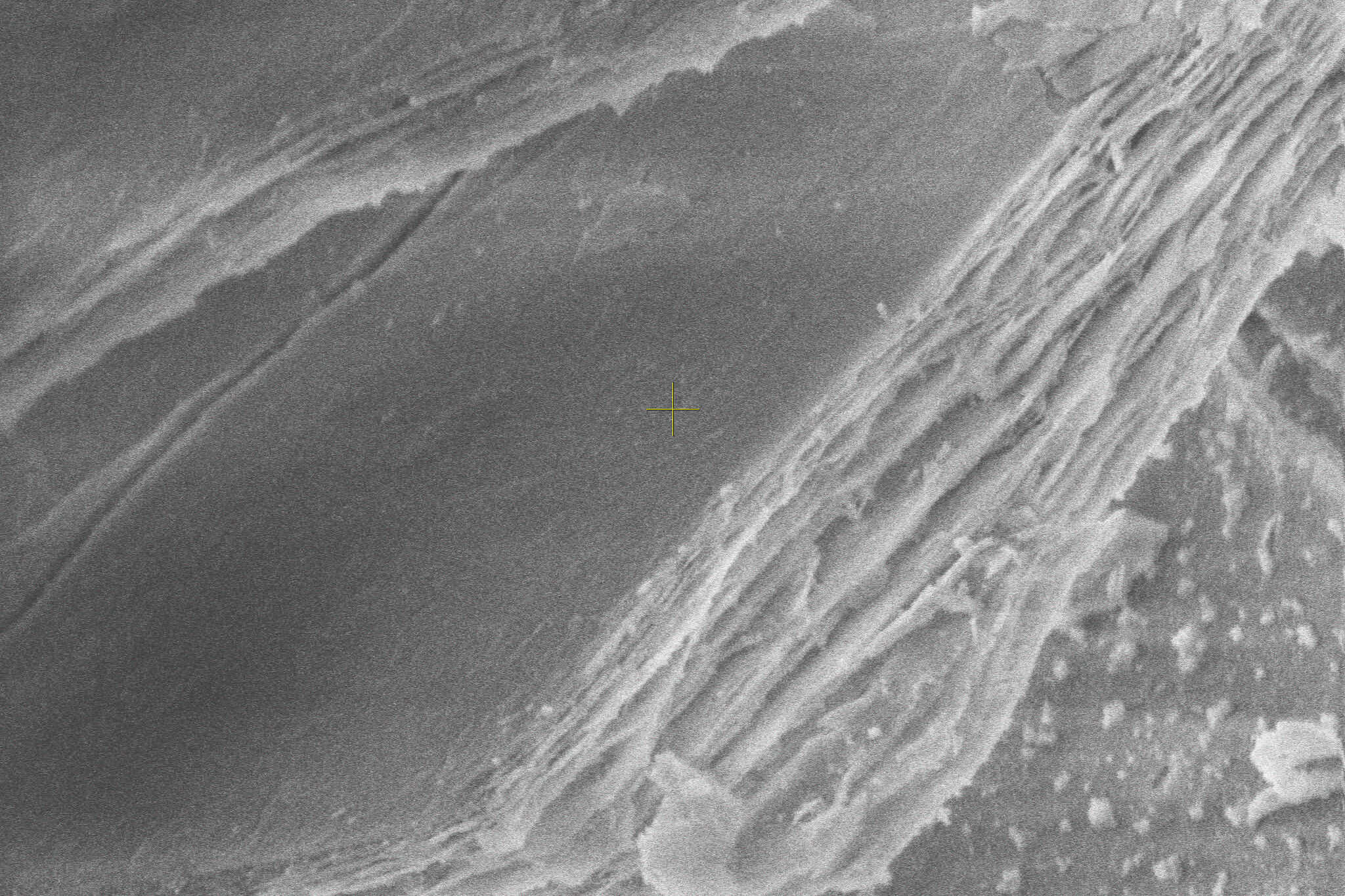

Interfaces between liquid metals were discovered to form a successful reaction environment for synthesising the two-dimensional materials FLEET was investigating for future low-energy electronics.

An entirely new process was born that allows access to previously unattainable novel materials.

This ‘once in a decade’ advance was described as so cheap and simple it could be done on a kitchen stove.

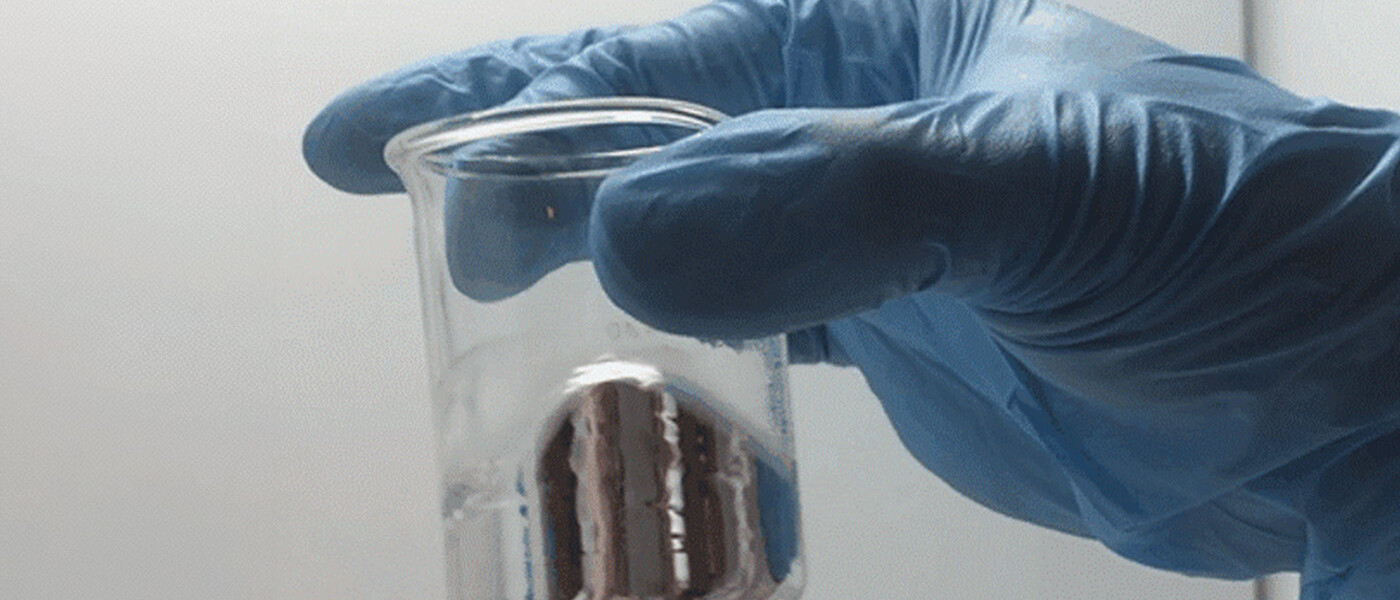

Metals that are liquid at room (or relatively low) temperatures include gallium (with a melting point of 30 °C), indium (157 °C), tin (232 °C) and bismuth (271 °C).

Material synthesis technologies using these metals allow:

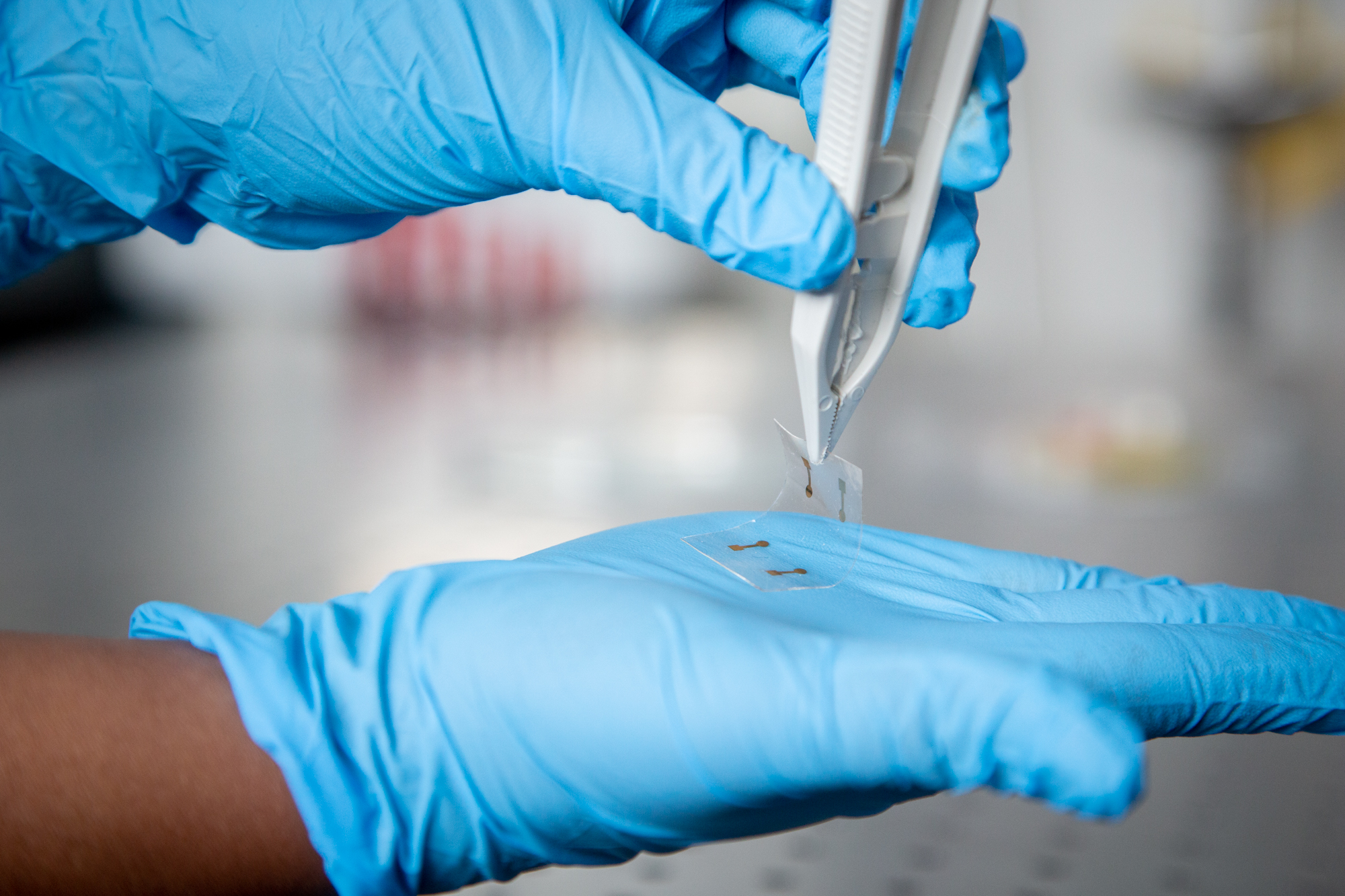

- Liquid-metal touch printing of new electronic materials

- Manufacture of protective layers for delicate novel materials, allowing integration into functioning devices (for example, allowing room-temperature exciton trapping – see the case study)

- Creation of never-before synthesised materials that offer new applications.

And those new materials are just the start…

The new liquid-metal processes allow advances that will have direct benefits for our environment and for a more-sustainable future, including innovative carbon-capture technologies, water filtering, and low-energy hydrogen catalysis for alternative energy systems.

These technologies have all sparked further research, attracting external funding, and at least one spin-off company has been formed.